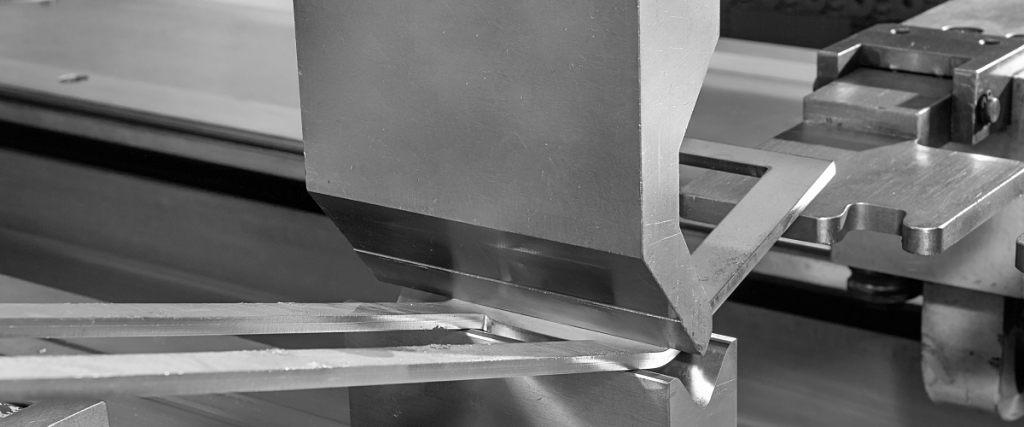

Engineering is our " blood group". Our number one priority is to build relationship with bussines partners based on trust. In our field we focus on good quality work. We keep on developing and we try to take advantage of the latest trends not only in production but also in the way we manage our company. Our main strength is quick reaction to given task and AGILE solution of all processes.